PRACTICES

01

01FACTORY MANAGEMENT

02

02VENEER AND LAMINATING

03

03PANEL SIZING

04

04NESTING

We are the first architectural woodwork factory in the United States to install a Bargstedt automatic storage and retrieval system. We robotically store and collate the materials for all our automated manufacturing operation. This has drastically reduced the labor drain and costs associated with material movement

Through our global reach we are able to obtain the highest quality woods directly from the manufacturing source. We also employ fully automated laminating equipment that delivers high quality while minimizing production labor costs. We hot press all material with a PVA ridged bond that is stronger that the wood fiber it connects to.

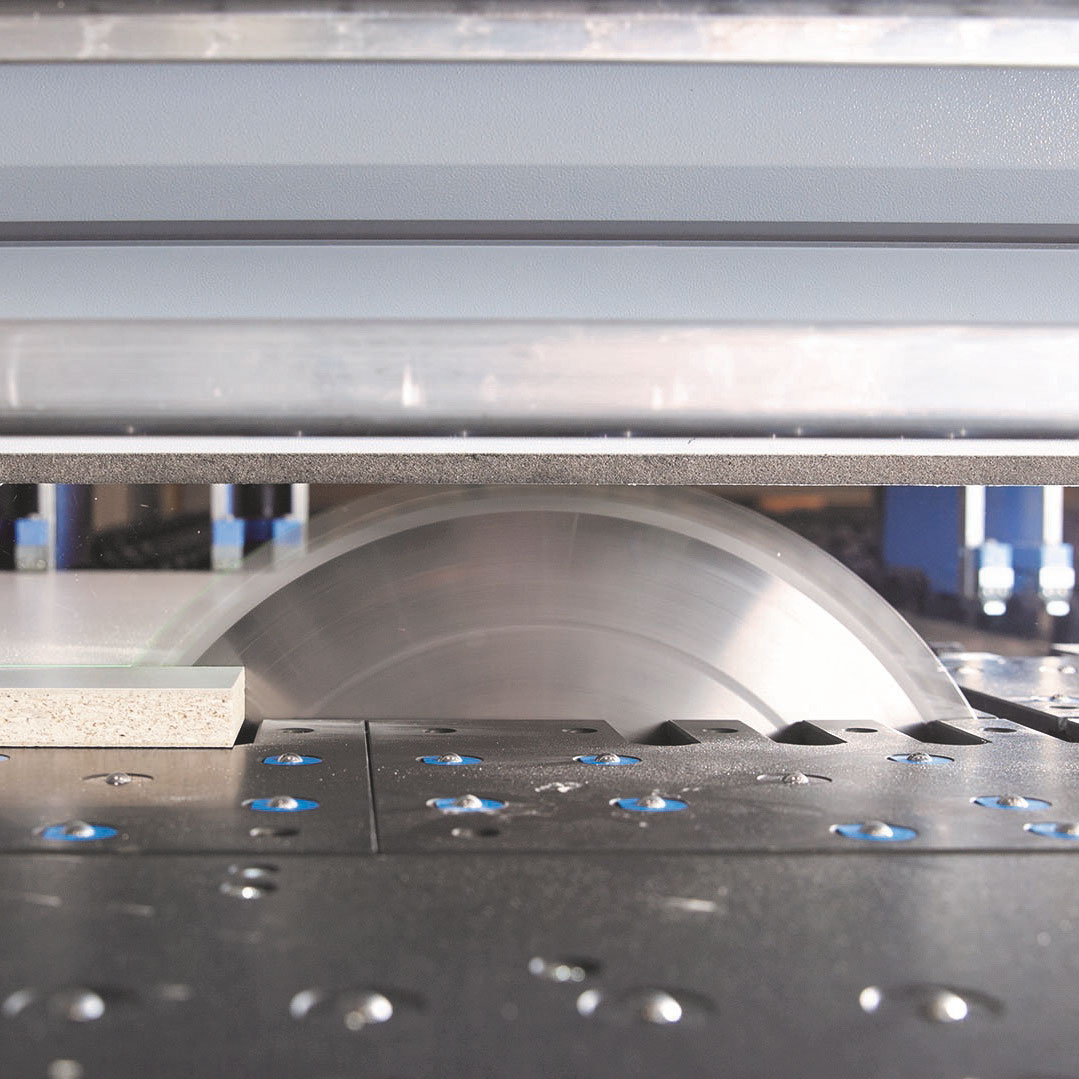

Our Homag HPL 380 saw has a production capacity of 300 panels per shift, automatically delivering panels to be processed through its rear load feed system. Our saw opera-tor uploads work orders through our digital network where computer programs optimize and then cycle the cutting pattern. Each cut part receives an automatically generated bar coded label that routes its production path.

We were the first in the industry to install an automatically fed CNC flat panel nesting machine line, a feature which further drives down our production labor per part. This system, in concert with our automatic laminating line and material handling system insures that the first time a human hand touches the millwork part it is completely machined - thus driving our labor coefficient down.

05

05CONSTRUCTION DOWELING

06

06EDGE TREATMENT

07

075-AXIS MILLING

08

08WORK IN PROGRESS

As with traditional cabinetmakers, we prefer to dowel our joinery. This old world connection is delivered via our high tech CNC driven, bar-code controlled, Weeke 100 robotic dowel shooter. The machine will read the part bar-code, travel to the exact dowel location, drill the required hole and insert the specified dowel. It is also specifically positioned within our lean shop layout so that the function can be performed fluidly.

Edges are critical to millwork quality. The Homag KAL 310 is a PC based fiber optically controlled multi-function machine that will mill all edge surfaces to a perfect chip free edge. The diamond tipped tools, preheated board, and thermally activated adhesive apply an edge of wood, plastic or PVC with heat and pressure. This edged part is then trimmed, milled, filed, cleaned and buffed before being returned.

The Homag BMG 512 5-axis milling machine is perhaps the most technically advanced machine in our factory. The two beds ensure that loading and unloading the machine creates efficient production. With a 12-inch z-stroke, the BMG 512 can handle large scale projects. This system, however, can not only be used as a milling machine, but with edge-bending capacity, it has multifunctional capacity.

Organization is key in a business that demands precision on every level. Our flow of machined parts is managed by housing in-progress parts in custom engineered carts - technology borrowed from the auto industry. Each cart is designed for a specific production route. The carts are tagged and tracked by work order. This system affords us great flexibility and has eliminated redundant handling.

09

09FINISHING

10

10ASSEMBLY

11

11PACKAGING AND DELIVERY

12

12INSTALLATION

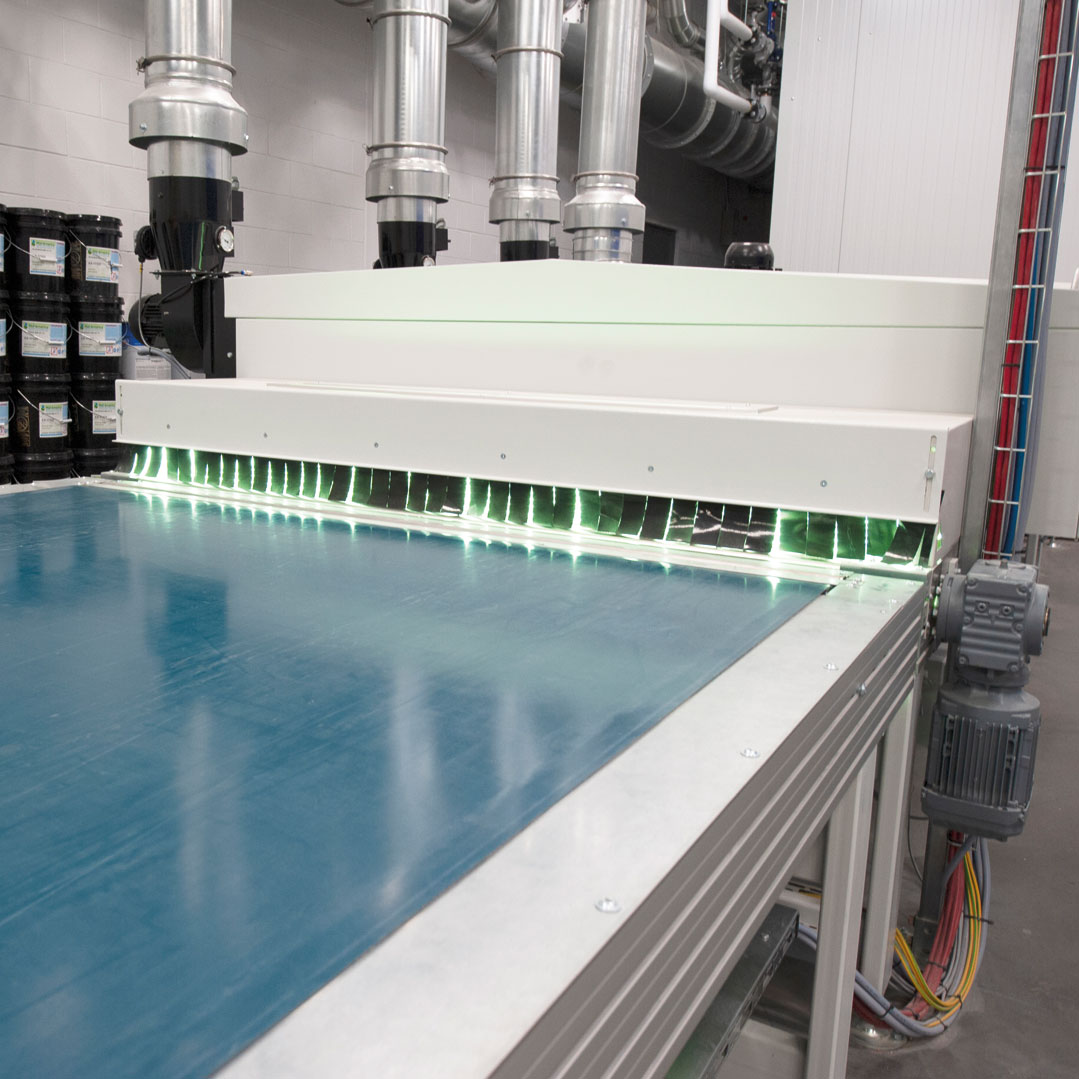

Operating as a conveyor, our Burkle Spray Finishing Line begins by cleaning the wooden surface with a brush and vacuum. The surface then enters the spraying chamber where it is coated in a water-based finish. Before entering the dryer, the surface moves along a setting conveyor to ensure proper drying. For final curing, the piece then moves under a series of UV lights before heading off to get sanded and stacked.

We have implemented a semi-automatic assembly line for typical case goods. Many of the diverse projects we produce require some assembly work outside our production line. To meet that need we have a robust bench department which does not compromise excellence for productivity. Our lean bench work cell affords maximum efficiency in movement for our cabinetmakers, allowing us to maximize both quality and value.

Our material is packaged on custom designed carts, Carted components are covered with plastic stretch wrap and bar-code labelled by our custom information management system. These wrapped packages are electronically tracked and mechanically delivered. This saves time on demanding loading docks/hoists and facilitates job-site material management. After unloading, the carts are recycled for future deliveries.

It is in the field that time and space are in the shortest supply, labor the most intensive, and sequencing requires the most vigilant focus. On site we have worked to refine operations to maximum efficiency through lean work cell concepts that are also mobile. Our customized gang boxes have been built to hold our installation tools in efficient order and the box itself has been modified to open for easy access.